Selection of materials and processes, along with validation based on the application, are the foundation of structural integrity and mission success for vehicles such as spacecrafts, rockets, missiles, and aircrafts. The selected materials and processes are considered Single Point Failure items because any glitch in them could jeopardize the mission success of multimillion-dollar vehicles. The founder of LM&P ENGG FELLOW, LLC, Paresh R. Modi, is recognized as an expert in this science and engineering based on his educational background and over 40 years of industrial experience.

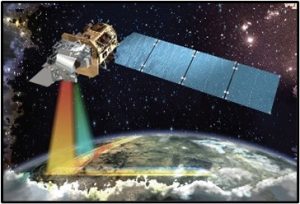

For example, spacecrafts are launched into Geostationary Earth, Medium Earth, and Low Earth Orbits depending on the application. The 9,700-pounds GPSIII (Global Positioning System) SV01 spacecraft of the Space Force was launched into MEO, the 11,000-pounds Geostationary Operational Environmental Spacecraft (GOES-R) of NASA was launched into GEO, and the 24,500-pounds Hubble Space Telescope of NASA was launched into LEO. The selected materials must be compatible with LEO, MEO, or GEO, depending on which orbit the spacecraft will operate in during its planned lifetime (~ 15 years). The presence of ultraviolet radiation in LEO converts 96% of Oxygen to Atomic Oxygen. Atomic Oxygen is very reactive and energetic enough to break chemical bonds on the surface of many materials, reacting with them to form oxides.

Therefore, the selected materials and processes are validated by LM&P ENGG FELLOW, LLC before the fabrication of spacecrafts, rockets, missiles, and aircrafts based on their environmental exposure, intended functionality, and lifespan.

A typical vehicle comprises many systems such as, structure and mechanisms, propulsion, thermal, electrical and electronics, power, attitude control, payload, and communication/command/data handling. Each system requires precise selection of materials and processes for fabrication of parts, components, sub-assemblies, and assemblies. The selection is based on the application and functionality of the system, space environment including temperature extremes and radiation effects, compatibility of materials, expected degradation / corrosion control, lifespan of the vehicle, etc. Adequate knowledge and experience in material science and engineering, metallurgical engineering, process engineering, corrosion science & control including galvanic and stress corrosion, fracture mechanics, and failure investigation & analysis are necessary. With a wealth of knowledge and over 40 years of industrial experience, Paresh R. Modi has dedicated his career to understanding the complexities of science & engineering and developing innovative strategies for 100% mission success of the vehicles.

Paresh R. Modi’s approach to materials & process engineering is both comprehensive and cutting-edge. He offers a range of techniques to ensure flightworthiness of the parts. He certifies raw materials and processes before the fabrication of parts. He ensures parts are free of degradation using certified non-destructive testing. He establishes Fracture Control Plan and performs Fracture Mechanics Safe Life Analysis using NASGRO to predict safe life of the critical parts. For new or suspect design, if required, he evaluates accelerated life testing of components based on Coffin-Manson / Weibull models. The goal is to achieve zero tolerance for parts failures.

For any unexpected failure, Paresh R. Modi performs thorough investigation and failure analysis to pinpoint the root cause and implements corrective actions ensuring no reoccurrence of this or similar failure.

Through numerous contributions to the industries, Paresh R. Modi has helped countless organizations with the reliability of the products delivered to the mainstream market. His consulting services not only address the immediate challenges of products but also contribute to the development of more sustainable and resilient products and systems for the future.

The business of LM&P ENGG FELLOW, LLC, a Federal Government Contractor (SDC), is registered with SAM.GOV, NASA SBC OSBP / NVDB, DLA, SBIR, DARPA, ARMY, SBA, Space Alliance Technology Outreach Program affiliated with NASA JSC, etc. The founder, Paresh R. Modi, DOD Secret Clearance, has over 40 years of industrial experience, which includes 34 years of unparalleled contributions to our national giant defense contractor Lockheed Martin Corporation with unprecedented loyalty.

Recently, we successfully performed fracture mechanics analysis of bipropellant tank (end user: NASA) after establishing Fracture Control Plan and thorough review of materials & processes with compatibility studies; the propulsion system of the mini space vehicle is successfully performing required functions on-orbit. We performed galvanic & crevice corrosion analysis of a monopropellant tank (end user: DOD) and delivered instructions for mission success prelaunch safety package. Also, we delivered Fracture Critical Hardware Disposition Report for the acceptance of a Bi-Propellant tank (end user: Raytheon). The spacecraft refueling service of N2H4 is one of the outstanding concepts (end user: DOD). For the fuel transfer valve mechanism, we performed materials compatibility studies including stress / crevice / galvanic corrosion analyses and other analyses such as cold welding, creep, atomic oxygen, internal charge buildup, etc. and ensured the system meets NASA Range Safety requirements. We analyzed the thermistor debonding issue, pinpointed root cause, and fixed the problem. We completed two projects with the Space Alliance Technology Outreach Program that is affiliated NASA JSC. We reviewed science of Electronics box and provided corrective actions for application of mini space vehicles.

For organizations looking to mitigate the risks associated with end products, partnering with LM&P Fellow – Paresh R. Modi is a crucial step. His deep understanding of science and technology, coupled with his extensive practical experience in applying safety measure techniques, makes him a valuable resource for any industry where product integrity is vital.

Copyright 2026 © LM&P ENGG FELLOW, LLC All Rights Reserved.